final project: 3d printing

November 17, 2020

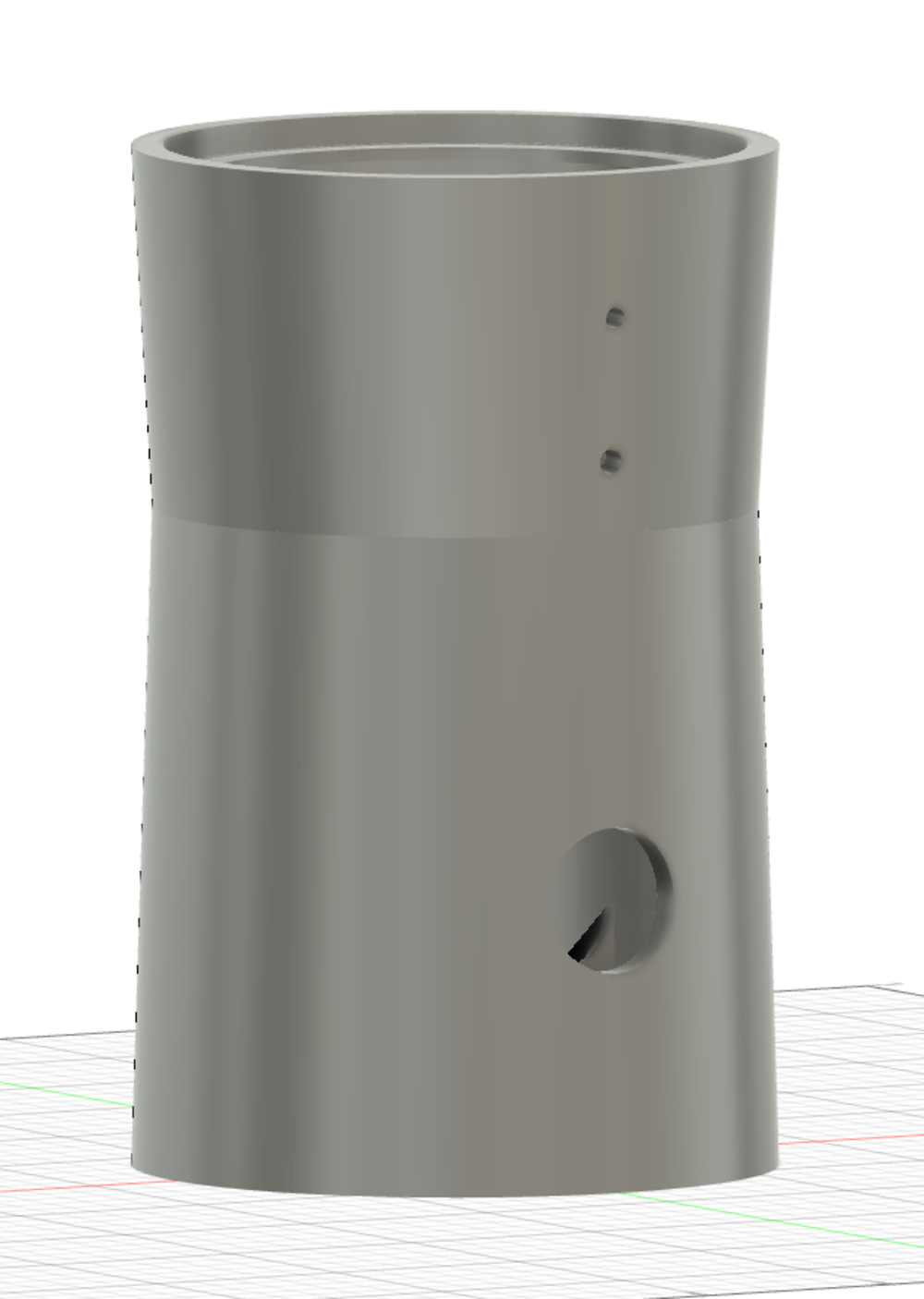

final project device housing

Now that all of the internal components are completed for my final project, it was time to print out the entire device housing. I had to make some edits to the size of the housing so that it would fit all of the internal components. I also had to leave some extra space to allow room for wires to slide through.

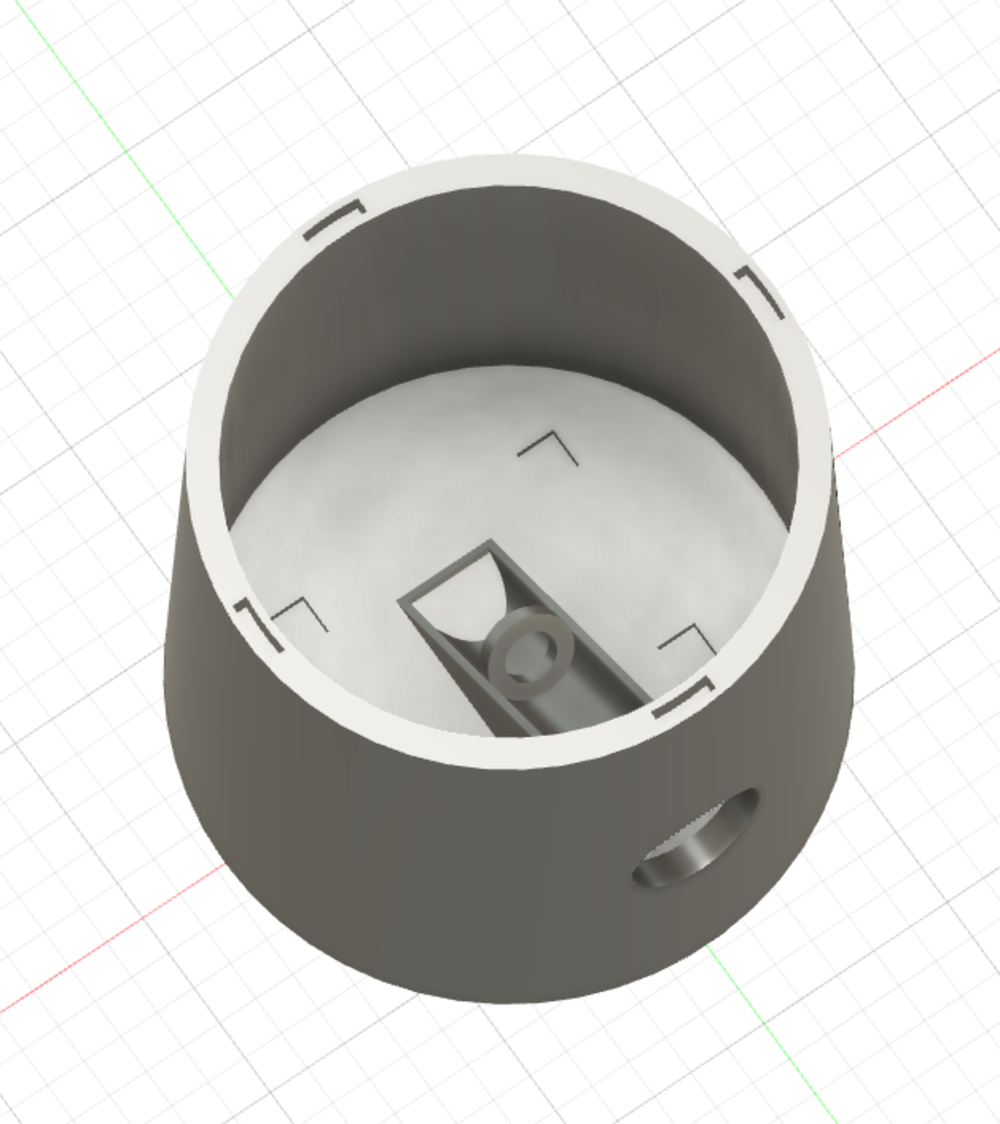

I added an extra hole for the speaker to emit a louder sound. Additionally, I added inserts for the stepper motor housing to slide into and had the solenoid housing built into the bottom of the device so that it would stay in place.

Additionally, since the 3D printer couldn’t cut that high, I split my device into two halves and made joints that would connect the two halves. I wanted to print my parts on the uPrint in the eecs shop, however, my parts were too large and wouldn’t fit the bed, so I had to print them on the Sindoh 3d printer.

I added an extra hole for the speaker to emit a louder sound. Additionally, I added inserts for the stepper motor housing to slide into and had the solenoid housing built into the bottom of the device so that it would stay in place.

Additionally, since the 3D printer couldn’t cut that high, I split my device into two halves and made joints that would connect the two halves. I wanted to print my parts on the uPrint in the eecs shop, however, my parts were too large and wouldn’t fit the bed, so I had to print them on the Sindoh 3d printer.

CAD of my final project device housing

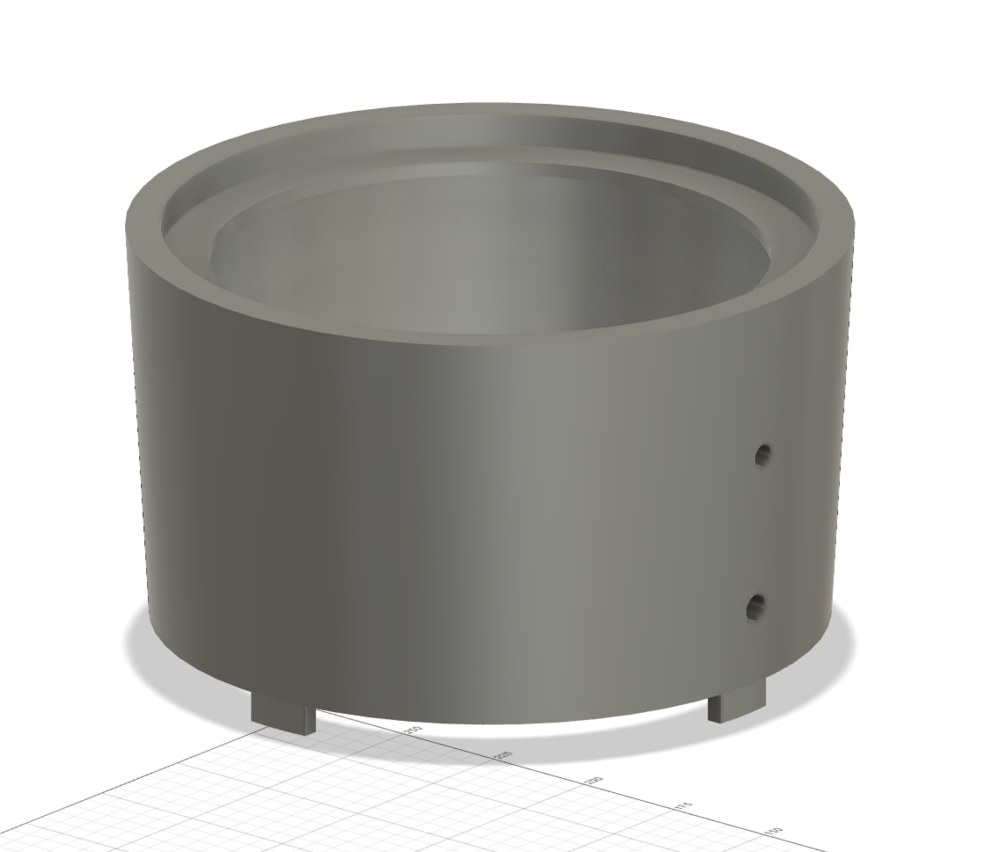

CAD of the top half

CAD of the bottom half

I printed each half over two days and overall it turned out much larger than I expected. My design was constricted by the size of the stepper motor since my inserts on my disk had to be far from the center so the stepper motor itself wouldn’t interfere. But overall the print looked nice and the two pieces together looked very cool. I tried to keep the hourglass shape, however, it was hard now that the top and bottom base were both very large.

Top half of housing printed

Bottom half of housing printed

Solenoid flush with bottom half of housing

Stepper motor housing fits with bottom half of housing

Both halves of the housing combined

One oversight was that I forgot to include a hole for my wall outlet to connect to. Therefore I had to drill a hole that would fit the barrel jack in the back of the device. This was pretty self-explanatory and worked out nicely.

Hole drilled for the barrel jack

lid

The last feature I needed to add was a lid. I used Fusion360 to design a lid that would fit right on top of my housing. Below is my CAD

CAD of device lid

Lid printed

NEXT>