Laser Cutting

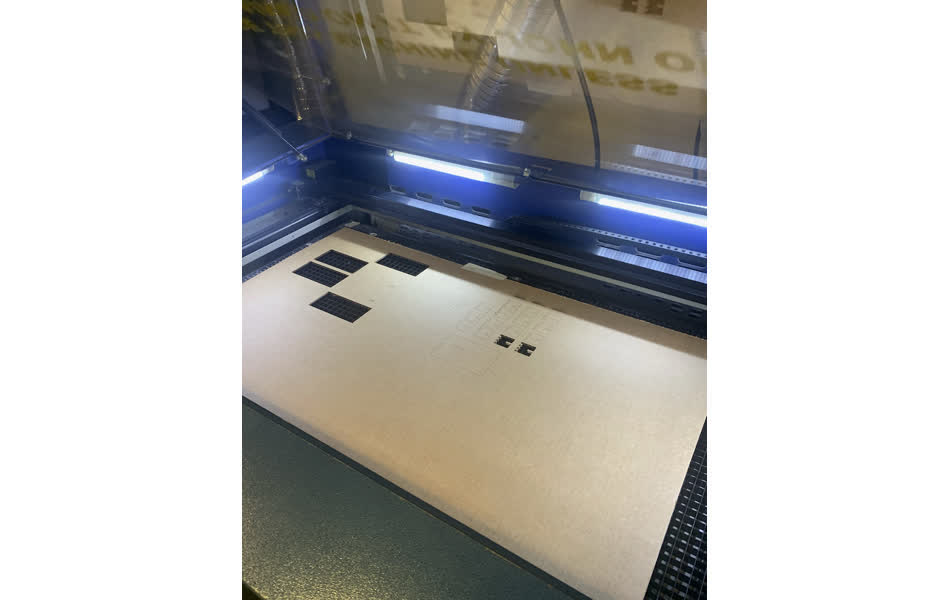

For our group assignment, we determined the kerf (material thickness + width of burned laser cut lines) as well as the settings that work best for a smooth cut. Configuration: Thickness: 4.0-4.3mm Speed: 2.2-2.5Power: 100 PPI: 200

Vinyl Cutting

I explored different materials (traditional vinyl and mylar). Mylar failed the first time because it didn't have a rigid backing, which is good to know!

Final Product: GeoDome

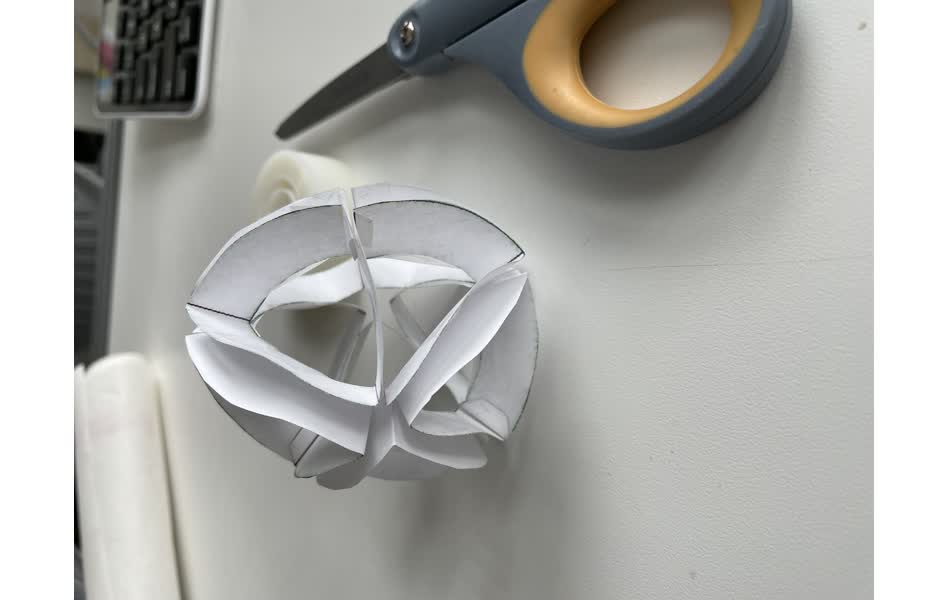

I explored many ideas and wanted to challenge myself to utilize living hinges in the assembly. In the end, I decided to make a construction kit for a spherical tetrahedron, but it is a bit hard to grasp mentally. So I decided to test on paper first before moving to cardboard and the laser cutter. Once I have grasped the concept, I created the design in Fusion 360.

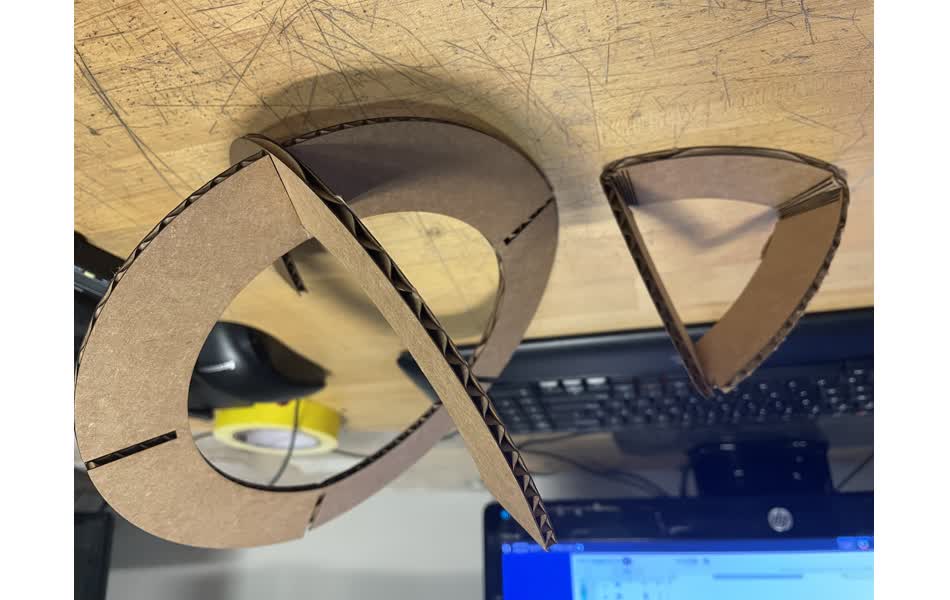

I tested with one hinged arc to see whether the joints and slots work and they fit snuggly. I also accidently created some brutalist artwork when I laser cut the little joint pieces. Hashtag accidental brutalist.

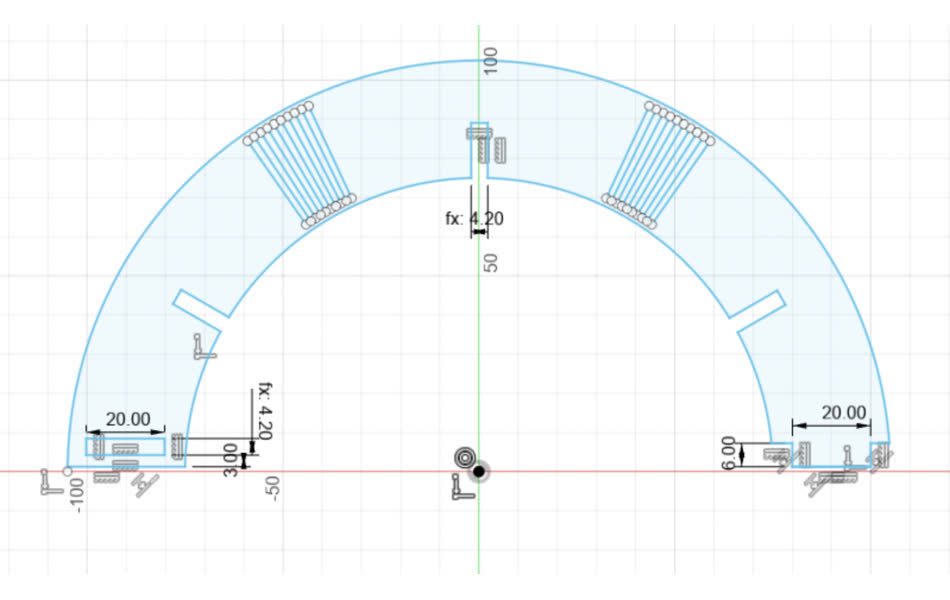

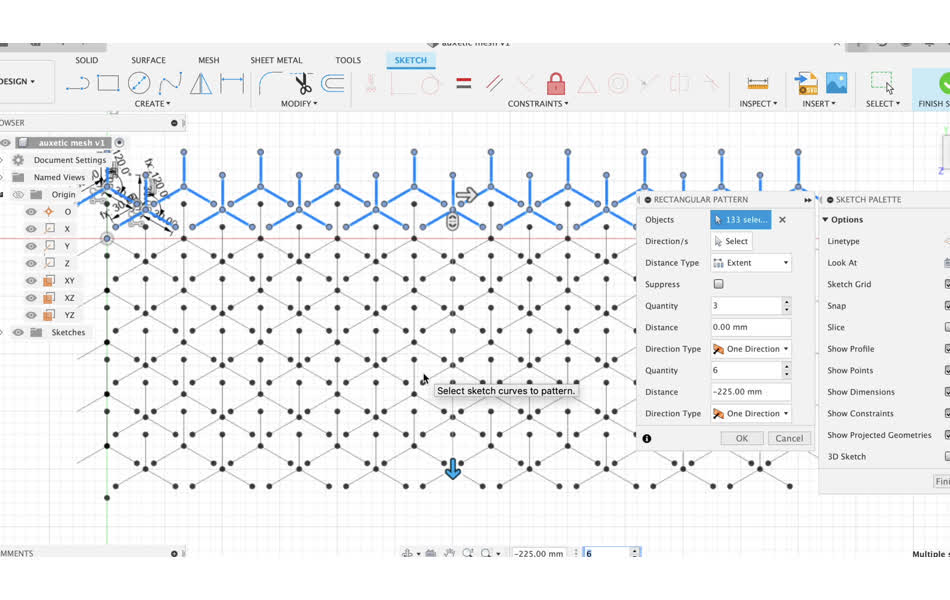

I would like to create an auxetic mesh that can be the skin of my spherical tetrahedron. Here is a parametric sketch I made in Fusion.

Assembly time! The littel triangle pieces connected via joints and slots but the mesh skin has to be taped to the cardboard. I made a critical mistake not considering that the wax paper is super hard to glue on but little glue dots worked super well (thanks glue dot).

Lastly, Jack and I did a little photoshoot session. It wasn't meant to be a helmet but it looks kinda funky which I like. And GeoDome disco ball! (see video)