pcb milling.

This week I learned how to mill my own pcb board and solder different parts onto to it to create a completed circuit. Initially, coming into the class, this "skill" was not one I was particularly excited for, but I had so much fun learning this week! I truly did not realize how much effort goes into designing a circuit.

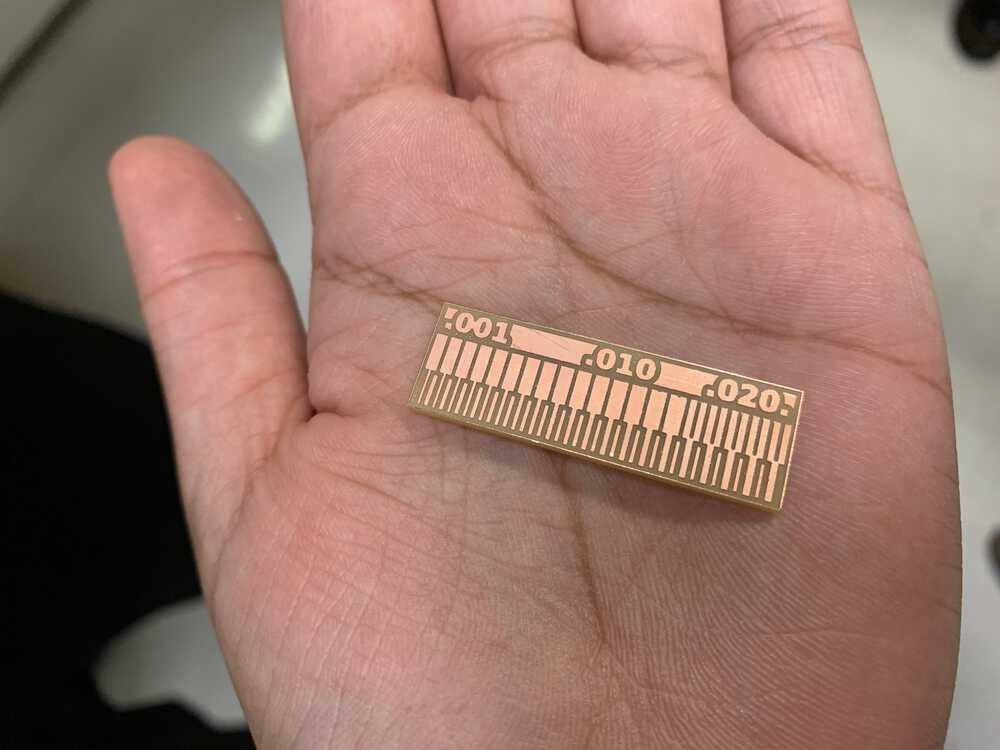

Once again, this week I had no idea what I was doing. Thank god for trainings! I went to PCB mill training on Friday, which was led by Zach. I feel I sort of had an unfair advantage in this training since Zach chose me to be his assistant, so I was actually able to step through the process of using the mill instead of just watching like the others. Obviously, doing something with your own hands allows the material to stick better in your head! During the training, we milled the trace width board, which was very helpful to understand what "offset" meant.

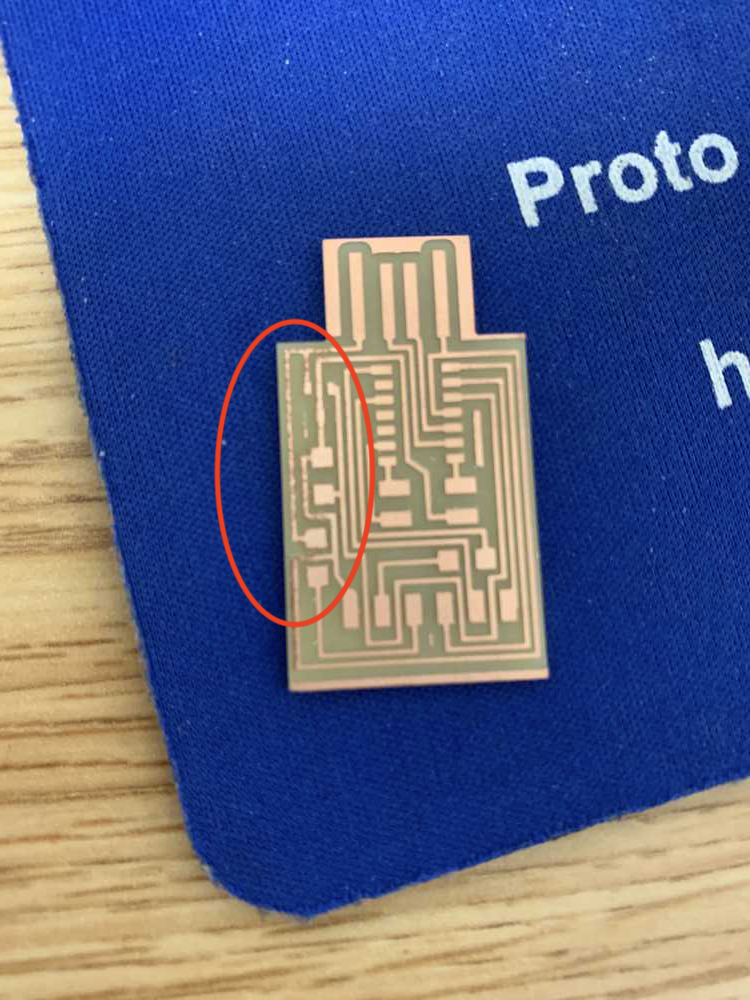

Then I was not able to come in to the shop on Saturday, so I came in on Sunday. I probably got there 8, after finishing dinner. I was heading in, Manu was heading out to get dinner. She said she would be back, so if I needed help, I could ask her. I started using the mill and was having difficulty with the board lying completely flat. I don't have a picture, but the first board I attempted to mill faded away in one corner and was not deep enough at other parts. So I repositioned the tip at the center of the board. This time, the board was a bit better, but randomly one part of it looked like it had been corroded away (see the left side).

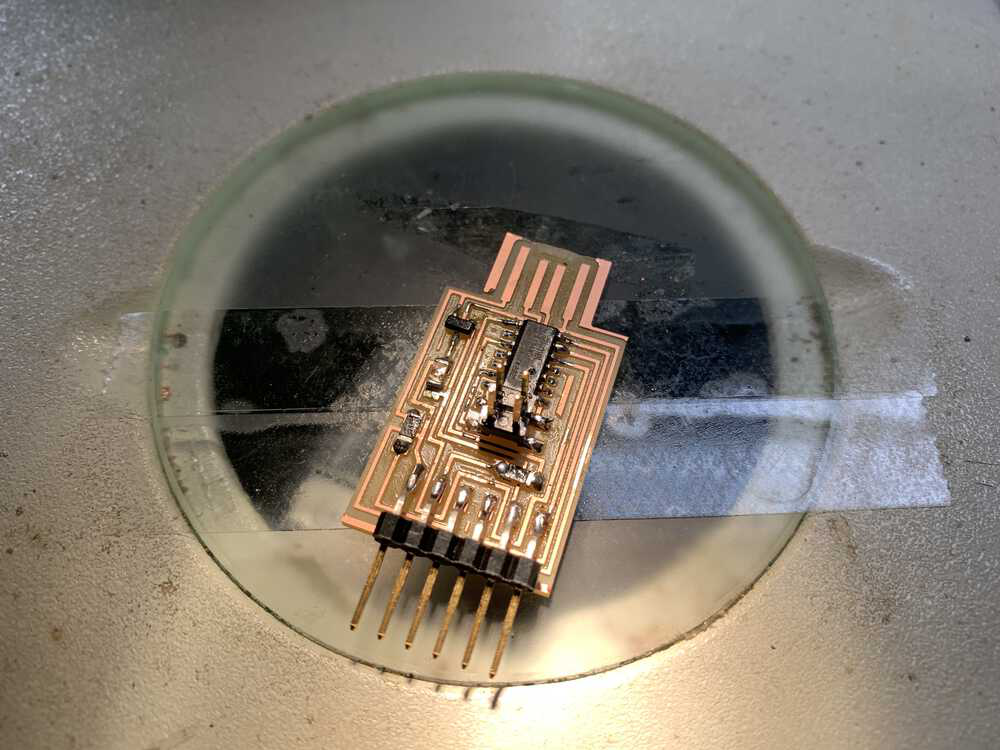

It was around 9 now, and I had to run to go to office hours for another class. So I left and came back around 10:15. This time with Manu's help, I milled my third board. She gave me the tip to apply the tape in a grid pattern instead of just in one direction. She also suggested that I deepen the cut. These seemed to help and I finally was able to mill a decent board! That night Manu and I played music and hung out in the lab while working on our projects. It was a fun time! Manu also taught me about where to find all the different components of the circuit. (I was making the SAMD11C board.) She also helped get set with soldering and I soldered on the two resistors that night. I was still not feeling totally confident about soldering (since I hadn't done it in 2 years), so I also I showed up to Zach's Monday soldering party to see what additional tips he could give me. Here's me soldering:

This was very helpful! With Zach's assistance, I was able to finish soldering the board. Additionally, I was able to learn about using a braid to separate solder "globs," as I like to call them. I also never actually knew what flux was, so that was good to learn about as well. Here's my final board:

The voltage regular was particularly tricky to solder on, as it s asymmetrical. I had so much fun this week! Didn't even know that this side of "making" existed. Very excited to learn how to use the board and program it. I'd also like to learn how to design my own boards in the future.