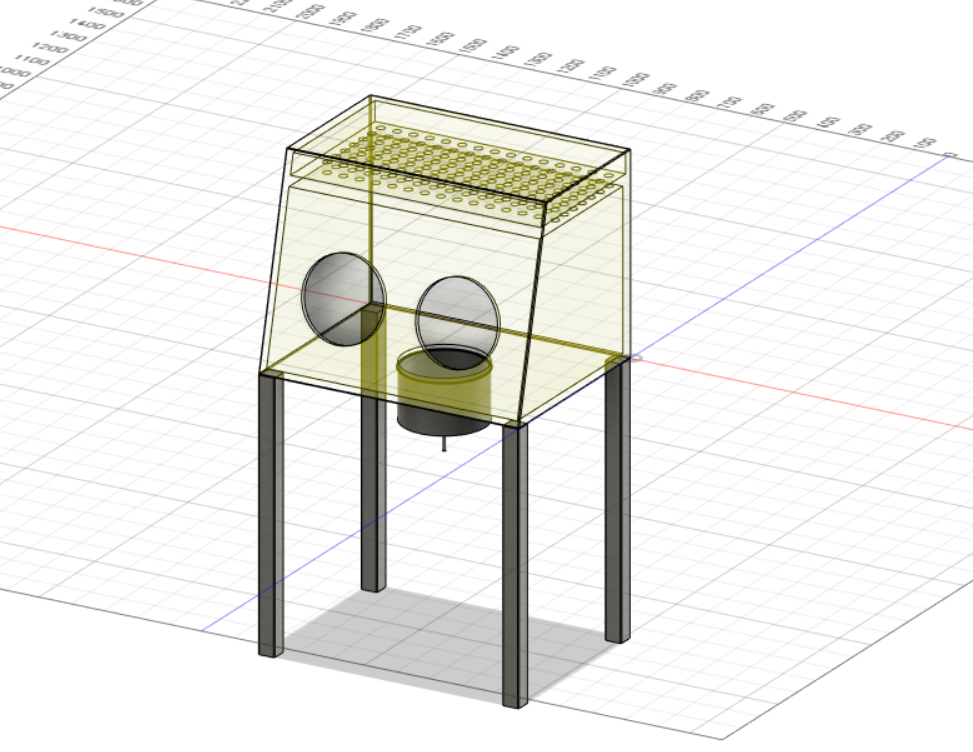

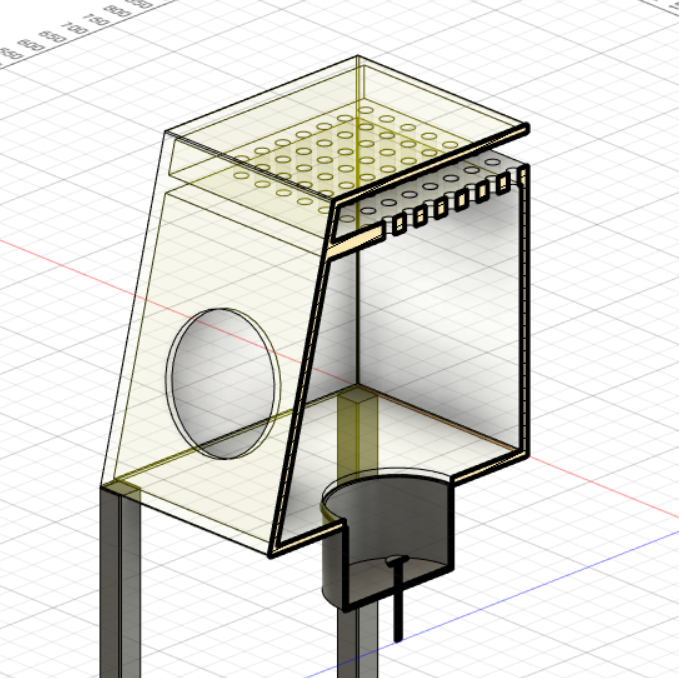

My goal is to make cleanroom space more accessible. Cleanroom space is required for most micro- and nanofabrication used in the semiconductor industry (e.g. solar cells, LEDs, computer chips) and any sort of microscale patterning (e.g. metasurfaces, flexible electronics, wearable sensors, etc). While cleanroom space is such a key requirement in developing new electronics, it is not readily available to most makers and inventors in the world due to the immense cost of constructing, operating, or even using external cleanroom space. This will change with the introduction of Fabubox, a portable and modular clean box system that allows integration of basic microfabrication processes such as sample cleaning and resist development, spin coating, mask aligner, and etching in a small enclosed clean environment without the necessity to maintain an entire cleanroom facility. A system comprised of just three Fabuboxes allows for a large number of microfabrication processes to be carried out in a regular "dirty" machine shop, maker space or anywhere else desirable.