Kim

0

1

10

11

100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

final

Drawing parts in parametric makes the 3D model and drawing more resilient to the change of material thickness, size, and other internal and external factors. Then what about let design be parametric?

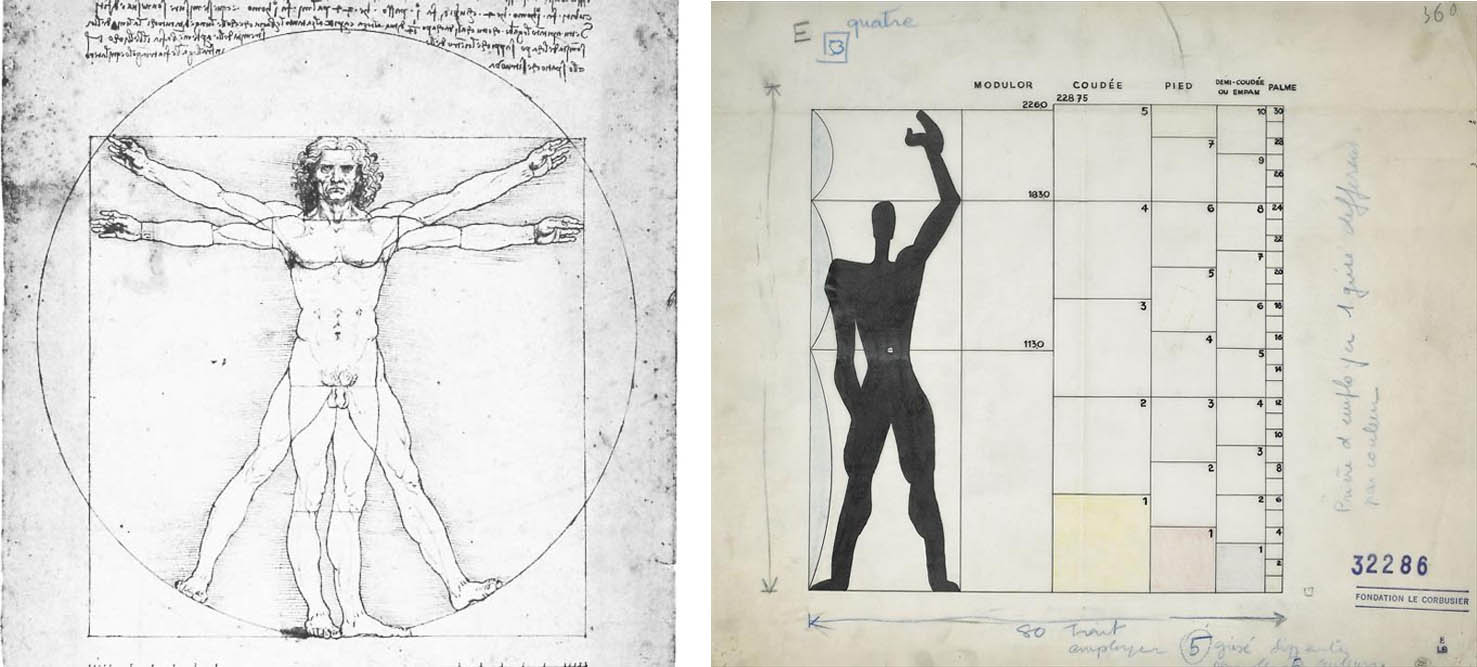

In design history, there are amny examples of using human body dimensions to create perfect human scale furniture and buildings. However, they often fall into the false myth of average or problem of customization. Now, Thanks to parametric, we are able to make perfect stool for individuals based on body shape and dimensions. (Vitruvius Man Le Modulor)

The first step to have your perfect stool is knowing yourself. Measure body parts that will define dimmensions of the stool. Calves, various measurements of hip, and your weight for the structural stability.

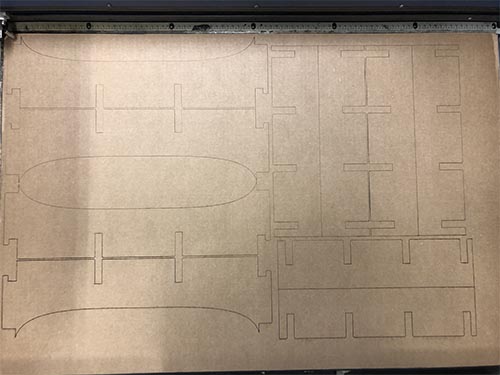

I made a parametric stool from Grasshopper which automatically creates design from fabrication parts. You can put your private body measurements into control factors and generate the customed stool for you!

It is essential to know how to cut. However, realizing what you're cutting is also important, especially for materials that structurally behave differently depending on the grain.

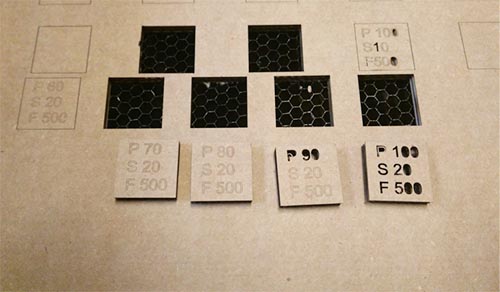

Through the group assignment, I got to learn how to set up laser cutter and range of acceptable cutting and scoring pwer/speed/frequenct for notches and joints. Beyond that, I was interested morphing the cardboard plate by scoring patterns.

I was fascinatec by the pattern of scoring can make plate behave in different ways.

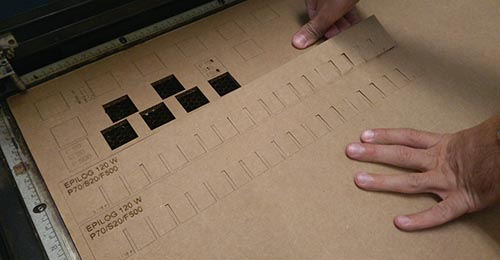

Parts are made in Grasshopper, considering kerfs. To make a stool, which has to be structurally stable, I had to consider corrugation direction. For example, vertical side plate and beam have ot have different dirrections of grain becuse the vertical part is taking vertical force and beams are transfering loads laterally.

The first prototype was successful. I could sit on it and even crossing my legs!

I was too excited to ask my friend to try out. He sat on it and "Crack!" the beam crushed immediately. I was pulling my hair and asked him "what... what's your weight?" He is 17pounds heavier than me. I'm not sure this shows that the engineering was too precise that the stool does not only fits to me but it can only bare me.

I learned a lesson and made some improvement in structure and joint details. Filleted the forner to make the part slot easier and add waffle plate to resist sheer force.

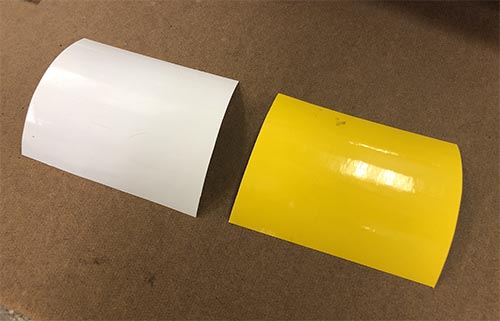

I made two stickers qith different colors that I can overlap to make silk screen style sticker.

1. Vinyl cutting

2. Laser cutting

3. Rhino API(Python), grasshopper

4. Laser cutting

5. mods

Files