Week 2 - Electronics Production

— weekly — 1 min read

In this week we are going to create a PCB. The premade design we were given is transforming USB signals to Serial. This board can come in handy later on when I design my final project.

First things first, we go to mods to turn our wireframe into a milling job. This step was luckily very straight forward since the group before me had already managed to come up with the correct numbers. So once this is done, I placed the copper on the machine's bed, inserted the endmill in it's designated place and calibrated it's height. BUT! I forgot to rotate the endmill again so the milling wasn't deep enough. Had to restart the entire thing and here is the result:

Next is soldering. These are the tools we are going to work with:

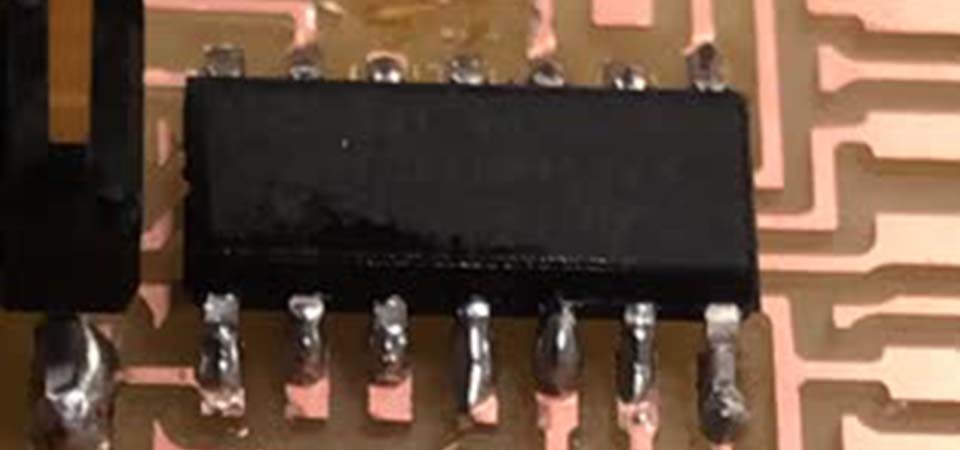

I have never soldered in my life. And I was quite nervous about doing so for the first time. But there is not better time than a Sunday evening to do your first soldering. So, with some TA quick tips, I tried to stick those components into them traces. I think the most important tip is to first solder a small piece and attach the component to it so it doesn't move. Oh, and also start from the middle and expand so that you can have some room to work with. Finally, ended up soldering the micro-controller:

Not too bad! well moving on to the entire board:

A little blurry but a new PCB is born!